Die Module Eine Lösung für alle Prozesse

Enterprise Resource Planning – der Kern

Einkauf

Als Basis für Ihren Ertrag – Sie realisieren mit den Einkaufsprogrammen in winweb-food eine optimale Materialbeschaffung

Verkauf

Vom Angebot bis zur Rechnungsstellung – winweb-food verwaltet effizient alle Verkaufsprozesse und sichert flexible Datenauswertung

Qualitätssicherung

Protokollierung und Ergreifung notwendiger Maßnahmen direkt in den Prozesen – die systemgesteuerte Sicherung der Qualität Ihrer Produkte ist entscheidend für jede erfolgreiche Auditierung

Lager

Als Basis für Ihren Ertrag – Sie realisieren mit den Einkaufsprogrammen in winweb-food eine optimale Materialbeschaffung

Management-Info-System (MIS)

Auf Knopfdruck angezeigt – Ihre relevanten Unternehmenskennzahlen als Grundlage für Ihre Managemententscheidungen

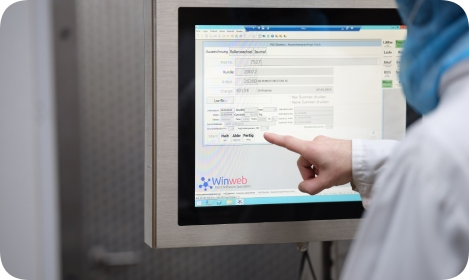

Touchscreen-Programme

Ergonomische Bedienung – speziell entwickelte und individuell einstellbare Bedienoberflächen beschleunigen die Erfassung betrieblicher Prozesse

Spezialprogramme

Chargenrückverfolgung

Als Basis für Ihren Ertrag – Sie realisieren mit den Einkaufsprogrammen in winweb-food eine optimale Materialbeschaffung

Ladensystem/ Filialabrechnung

Vom Angebot bis zur Rechnungsstellung – winweb-food verwaltet effizient alle Verkaufsprozesse und sichert flexible Datenauswertung

Schlachtung

Protokollierung und Ergreifung notwendiger Maßnahmen direkt in den Prozesen – die systemgesteuerte Sicherung der Qualität Ihrer Produkte ist entscheidend für jede erfolgreiche Auditierung

Elektronische Datenanbindung

Electronic Data Interchange (EDI)

Datenaustausch leicht gemacht – Volle Integration aller Formate, Partner und Datenübertragungskanäle zur Digitalisierung Ihrer Geschäftsprozesse

Mobile Datenerfassung (MDE)

Ortsungebunden erfasst – über MDE-Funk im System sofort integriert weiterverarbeitet

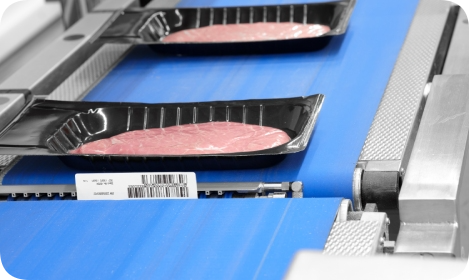

Computer Integrated Manufacturing (CIM)

Kommunikation von Produktion und Software – Integration Ihrer Maschinen und Anlagen als Weg zu einer optimalen Wertschöpfung und Auswertbarkeit der OEE

Integrierte Ergänzungsprogramme

Customer Relationship Management (CRM)

Gezielte Aktivitäten – Intergriertes Informations- und Steuerungssystem für Vertrieb, Marketing, Kundenservice und Projektmanagement

Dokumenten-Management-System (DMS)

Ihre Dokumente im schnellen Zugriff – Dokumentenechte Speicherung und Archivierung aller relevanten Belege vom Einkauf bis zum Verkauf vollständig integriert in winweb-food